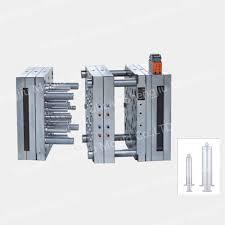

The design of the Syringe Mould cooling system for disposable syringe manufacturers is often regarded as a minor issue. Not enough attention has been paid to the size and structural design of the cooling system. Unreasonable cooling system design will cause internal stress for small plastic parts, and deformation and even stress cracking for large plastic parts with thin walls.

Moreover, insufficient cooling will result in prolonged molding cycle, thereby reducing production efficiency. Below, in some simplified forms, the complicated cooling process of the injection mold is studied, practical formulas are derived, and the method of determining the size of the cooling system is discussed based on these formulas. Determining the size of the cooling system is undoubtedly not a simple task. Generally speaking, mold designers are still unfamiliar with certain aspects.

What is the reason for the damage of the injection mold of the disposable syringe manufacturer?

(1) In plastic injection products, if there are metal inserts, when the metal inserts are placed in the mold, they are not firmly or skewed. After the mold is closed, local damage, indentations or pits in the molding cavity will occur.

(2) The mold is damaged due to the high pressure of the injected molten material, the fast flow rate, overturning or changing the position of the metal insert.

(3) The parting joint surface of the mold is closed for a long time, and occasionally impurities are caught in the middle or the sliding part of the template is worn for a long time. This causes the template to run non-parallel, which makes the tightness of the mold joint surface worse after closing, and it is easy to appear Problems such as flashing of molded products seriously affect product quality. At this time, the mold should be inspected and repaired.

Shengjiu is a professional manufacturer of Medical Mould, whose products are sold at home and abroad, please call to order products.

Moreover, insufficient cooling will result in prolonged molding cycle, thereby reducing production efficiency. Below, in some simplified forms, the complicated cooling process of the injection mold is studied, practical formulas are derived, and the method of determining the size of the cooling system is discussed based on these formulas. Determining the size of the cooling system is undoubtedly not a simple task. Generally speaking, mold designers are still unfamiliar with certain aspects.

What is the reason for the damage of the injection mold of the disposable syringe manufacturer?

(1) In plastic injection products, if there are metal inserts, when the metal inserts are placed in the mold, they are not firmly or skewed. After the mold is closed, local damage, indentations or pits in the molding cavity will occur.

(2) The mold is damaged due to the high pressure of the injected molten material, the fast flow rate, overturning or changing the position of the metal insert.

(3) The parting joint surface of the mold is closed for a long time, and occasionally impurities are caught in the middle or the sliding part of the template is worn for a long time. This causes the template to run non-parallel, which makes the tightness of the mold joint surface worse after closing, and it is easy to appear Problems such as flashing of molded products seriously affect product quality. At this time, the mold should be inspected and repaired.

Shengjiu is a professional manufacturer of Medical Mould, whose products are sold at home and abroad, please call to order products.

The design of the Syringe Mould cooling system for disposable syringe manufacturers is often regarded as a minor issue. Not enough attention has been paid to the size and structural design of the cooling system. Unreasonable cooling system design will cause internal stress for small plastic parts, and deformation and even stress cracking for large plastic parts with thin walls.

Moreover, insufficient cooling will result in prolonged molding cycle, thereby reducing production efficiency. Below, in some simplified forms, the complicated cooling process of the injection mold is studied, practical formulas are derived, and the method of determining the size of the cooling system is discussed based on these formulas. Determining the size of the cooling system is undoubtedly not a simple task. Generally speaking, mold designers are still unfamiliar with certain aspects.

What is the reason for the damage of the injection mold of the disposable syringe manufacturer?

(1) In plastic injection products, if there are metal inserts, when the metal inserts are placed in the mold, they are not firmly or skewed. After the mold is closed, local damage, indentations or pits in the molding cavity will occur.

(2) The mold is damaged due to the high pressure of the injected molten material, the fast flow rate, overturning or changing the position of the metal insert.

(3) The parting joint surface of the mold is closed for a long time, and occasionally impurities are caught in the middle or the sliding part of the template is worn for a long time. This causes the template to run non-parallel, which makes the tightness of the mold joint surface worse after closing, and it is easy to appear Problems such as flashing of molded products seriously affect product quality. At this time, the mold should be inspected and repaired.

Shengjiu is a professional manufacturer of Medical Mould, whose products are sold at home and abroad, please call to order products.

0 Reacties

0 Deel acties