- Male

- Gevolgd door 4 leden

Actueel

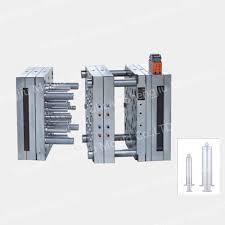

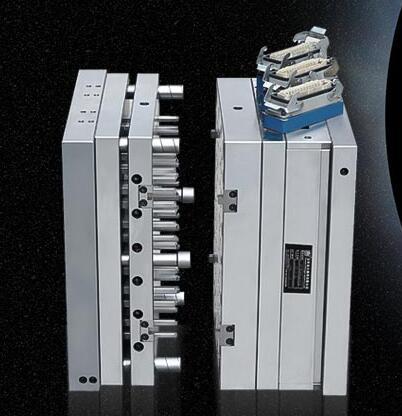

- Syringe mould design and manufacturing are closely related to plastic processing. The success or failure of plastic processing depends largely on the effect of mold design and mold manufacturing quality, and the design of plastic molds is based on the correct design of plastic products.

Yuhuan Shengjiu Mould Co.,Ltd, as a professional syringe mould wholesaler, provides customers with cost-effective products.

https://www.medicalmould.net/Syringe mould design and manufacturing are closely related to plastic processing. The success or failure of plastic processing depends largely on the effect of mold design and mold manufacturing quality, and the design of plastic molds is based on the correct design of plastic products. Yuhuan Shengjiu Mould Co.,Ltd, as a professional syringe mould wholesaler, provides customers with cost-effective products. https://www.medicalmould.net/0 Reacties 0 Deel acties - Today's editor mainly introduces to you how to prevent the molding shrinkage error related content of syringe mould. Since the shrinkage rate will change due to the injection pressure, for single-cavity molds, the cavity pressure in the cavity should be as much as possible. Unanimous. As for the multi-cavity mold, the cavity pressure between the cavities should be very small. In the case of a single cavity with multiple gates or multiple cavities with multiple gates, injection must be made with the same injection pressure to make the cavity pressure consistent. For this reason, it is necessary to ensure that the gate position is balanced. In order to make the cavity pressure consistent in the cavity, it is best to keep the pressure at the gate entrance consistent. The pressure balance at the gate is related to the flow resistance in the runner. Therefore, before the gate pressure reaches equilibrium, the runners should be balanced.

Because the melt temperature and mold temperature have an effect on the actual shrinkage rate, when designing the cavity of a precision injection mold, in order to facilitate the determination of the molding conditions, attention must be paid to the arrangement of the cavity. Because the molten plastic brings heat into the mold, and the temperature gradient distribution of the mold generally surrounds the cavity, which is in the shape of concentric circles with the main runner as the center.

Therefore, design measures such as runner balance, cavity arrangement and concentric circular arrangement centered on the main runner are necessary to reduce the shrinkage error between the cavities, expand the allowable range of molding conditions, and reduce costs. The cavity arrangement of the precision syringe mould should meet the requirements of balance of the runner and the arrangement of the main runner as the center, and the cavity arrangement with the main runner as the line of symmetry must be adopted.

Yuhuan Shengjiu Mould Co.,Ltd has accumulated a wealth of practical experience over the years, has won a large number of partners with mature scientific management, advanced precision design and excellent products, and adheres to the fundamental purpose of "quality first, integrity management". We sincerely hope that new and old customers will send samples and drawings to process, let us seek common development and create wealth together.

For more product information, you can click on the link below: https://www.medicalmould.net/medical-mould/Today's editor mainly introduces to you how to prevent the molding shrinkage error related content of syringe mould. Since the shrinkage rate will change due to the injection pressure, for single-cavity molds, the cavity pressure in the cavity should be as much as possible. Unanimous. As for the multi-cavity mold, the cavity pressure between the cavities should be very small. In the case of a single cavity with multiple gates or multiple cavities with multiple gates, injection must be made with the same injection pressure to make the cavity pressure consistent. For this reason, it is necessary to ensure that the gate position is balanced. In order to make the cavity pressure consistent in the cavity, it is best to keep the pressure at the gate entrance consistent. The pressure balance at the gate is related to the flow resistance in the runner. Therefore, before the gate pressure reaches equilibrium, the runners should be balanced. Because the melt temperature and mold temperature have an effect on the actual shrinkage rate, when designing the cavity of a precision injection mold, in order to facilitate the determination of the molding conditions, attention must be paid to the arrangement of the cavity. Because the molten plastic brings heat into the mold, and the temperature gradient distribution of the mold generally surrounds the cavity, which is in the shape of concentric circles with the main runner as the center. Therefore, design measures such as runner balance, cavity arrangement and concentric circular arrangement centered on the main runner are necessary to reduce the shrinkage error between the cavities, expand the allowable range of molding conditions, and reduce costs. The cavity arrangement of the precision syringe mould should meet the requirements of balance of the runner and the arrangement of the main runner as the center, and the cavity arrangement with the main runner as the line of symmetry must be adopted. Yuhuan Shengjiu Mould Co.,Ltd has accumulated a wealth of practical experience over the years, has won a large number of partners with mature scientific management, advanced precision design and excellent products, and adheres to the fundamental purpose of "quality first, integrity management". We sincerely hope that new and old customers will send samples and drawings to process, let us seek common development and create wealth together. For more product information, you can click on the link below: https://www.medicalmould.net/medical-mould/0 Reacties 0 Deel acties - The design of the Syringe Mould cooling system for disposable syringe manufacturers is often regarded as a minor issue. Not enough attention has been paid to the size and structural design of the cooling system. Unreasonable cooling system design will cause internal stress for small plastic parts, and deformation and even stress cracking for large plastic parts with thin walls.

Moreover, insufficient cooling will result in prolonged molding cycle, thereby reducing production efficiency. Below, in some simplified forms, the complicated cooling process of the injection mold is studied, practical formulas are derived, and the method of determining the size of the cooling system is discussed based on these formulas. Determining the size of the cooling system is undoubtedly not a simple task. Generally speaking, mold designers are still unfamiliar with certain aspects.

What is the reason for the damage of the injection mold of the disposable syringe manufacturer?

(1) In plastic injection products, if there are metal inserts, when the metal inserts are placed in the mold, they are not firmly or skewed. After the mold is closed, local damage, indentations or pits in the molding cavity will occur.

(2) The mold is damaged due to the high pressure of the injected molten material, the fast flow rate, overturning or changing the position of the metal insert.

(3) The parting joint surface of the mold is closed for a long time, and occasionally impurities are caught in the middle or the sliding part of the template is worn for a long time. This causes the template to run non-parallel, which makes the tightness of the mold joint surface worse after closing, and it is easy to appear Problems such as flashing of molded products seriously affect product quality. At this time, the mold should be inspected and repaired.

Shengjiu is a professional manufacturer of Medical Mould, whose products are sold at home and abroad, please call to order products.The design of the Syringe Mould cooling system for disposable syringe manufacturers is often regarded as a minor issue. Not enough attention has been paid to the size and structural design of the cooling system. Unreasonable cooling system design will cause internal stress for small plastic parts, and deformation and even stress cracking for large plastic parts with thin walls. Moreover, insufficient cooling will result in prolonged molding cycle, thereby reducing production efficiency. Below, in some simplified forms, the complicated cooling process of the injection mold is studied, practical formulas are derived, and the method of determining the size of the cooling system is discussed based on these formulas. Determining the size of the cooling system is undoubtedly not a simple task. Generally speaking, mold designers are still unfamiliar with certain aspects. What is the reason for the damage of the injection mold of the disposable syringe manufacturer? (1) In plastic injection products, if there are metal inserts, when the metal inserts are placed in the mold, they are not firmly or skewed. After the mold is closed, local damage, indentations or pits in the molding cavity will occur. (2) The mold is damaged due to the high pressure of the injected molten material, the fast flow rate, overturning or changing the position of the metal insert. (3) The parting joint surface of the mold is closed for a long time, and occasionally impurities are caught in the middle or the sliding part of the template is worn for a long time. This causes the template to run non-parallel, which makes the tightness of the mold joint surface worse after closing, and it is easy to appear Problems such as flashing of molded products seriously affect product quality. At this time, the mold should be inspected and repaired. Shengjiu is a professional manufacturer of Medical Mould, whose products are sold at home and abroad, please call to order products.0 Reacties 0 Deel acties - I believe that many girls do not like using Vaginal Speculum Mould when they are doing gynecological examinations. When obstetricians and gynecologists used the vaginal dilator to check, some girls even felt discomfort and pain. Will the vaginal dilator for female gynecological examinations hurt?

A speculum is mainly used for routine gynecological examinations and operations. Obstetricians and gynecologists use a vaginal dilator to check, mainly to see if your cervix is inflamed, if there is any abnormality in the vaginal mucosa, and to look at the vaginal discharge.

For the feeling of speculum examination of gynecological examination, there must be some discomfort! For the first time for a gynecological examination, it is inevitable to be shy and nervous in front of others, but how to follow the doctor's instructions, inhale deeply, exhale slowly, and relax as much as possible. This kind of discomfort is still acceptable to most women. Doctors also have a headache for nervous women, because the vaginal opening is muscular tissue. When you are over-tensioned, the speculum cannot be put in, let alone take vaginal secretions.

If you want to know more about Gynecology Mould or have any questions, please follow us.

https://www.medicalmould.net/mould-display/medical-mould/vaginal-speculum-mould.htmlI believe that many girls do not like using Vaginal Speculum Mould when they are doing gynecological examinations. When obstetricians and gynecologists used the vaginal dilator to check, some girls even felt discomfort and pain. Will the vaginal dilator for female gynecological examinations hurt? A speculum is mainly used for routine gynecological examinations and operations. Obstetricians and gynecologists use a vaginal dilator to check, mainly to see if your cervix is inflamed, if there is any abnormality in the vaginal mucosa, and to look at the vaginal discharge. For the feeling of speculum examination of gynecological examination, there must be some discomfort! For the first time for a gynecological examination, it is inevitable to be shy and nervous in front of others, but how to follow the doctor's instructions, inhale deeply, exhale slowly, and relax as much as possible. This kind of discomfort is still acceptable to most women. Doctors also have a headache for nervous women, because the vaginal opening is muscular tissue. When you are over-tensioned, the speculum cannot be put in, let alone take vaginal secretions. If you want to know more about Gynecology Mould or have any questions, please follow us. https://www.medicalmould.net/mould-display/medical-mould/vaginal-speculum-mould.html0 Reacties 0 Deel acties - Disposable syringe specifications:

1, 1ml, 2ml, 3ml

2, 5ml, 10ml

3. 20ml, 30ml

4. 50ml, 60ml

5.100ml

Disposable syringes can also be used to store liquid medicines, and can also be used to draw blood, and can also be used to add auxiliary liquid medicines to the infusion set.

Yuhuan Shengjiu Mould Co.,Ltd is a manufacturer and wholesaler of medical mould with a long history, please feel free to contact us if you need it: https://www.medicalmould.net/Disposable syringe specifications: 1, 1ml, 2ml, 3ml 2, 5ml, 10ml 3. 20ml, 30ml 4. 50ml, 60ml 5.100ml Disposable syringes can also be used to store liquid medicines, and can also be used to draw blood, and can also be used to add auxiliary liquid medicines to the infusion set. Yuhuan Shengjiu Mould Co.,Ltd is a manufacturer and wholesaler of medical mould with a long history, please feel free to contact us if you need it: https://www.medicalmould.net/0 Reacties 0 Deel acties - Gynecological medicinal suppository mold is a well-known brand engaged in the production of suppository mold production line in China. It produces and sells suppository molds related to the production line, and better takes the lead in the development of the industry.

For more information, please click here: https://www.medicalmould.net/product/gynecology-mould/Gynecological medicinal suppository mold is a well-known brand engaged in the production of suppository mold production line in China. It produces and sells suppository molds related to the production line, and better takes the lead in the development of the industry. For more information, please click here: https://www.medicalmould.net/product/gynecology-mould/0 Reacties 0 Deel acties - Because the curled part of the oxygen mask mould is in direct contact with the pilot’s facial skin, it is required to be comfortable, free of allergic reactions and special odors. From the perspective of the oxygen masks currently in service and under development in the United Kingdom, the United States, France and other countries, they all use soft silicone rubber materials that are resistant to aging, oxidation and ozone, and have no abnormal odor (for example, Sauer A hardness of 30-40 degrees silicone rubber ), it has sufficient elasticity and certain rigidity to maintain the shape of the cover.

Since the connecting part of the mask and the device needs to be guaranteed to have sufficient rigidity and strength, different strength, rigidity, and flexibility requirements are put forward for different parts of the oxygen mask to meet different usage requirements.

Since the bottom of the oxygen mask needs to be in contact with the human face, the edges of the products produced cannot fit well with the user’s face, and the edges of the products produced due to moulds and other reasons are not flat enough to ensure the contact with people For comfort, a rubber strip that fits the face is usually buckled on the mask. However, the rubber strips are generally assembled manually, which not only has low production efficiency but also greatly wastes labor. This kind of manual assembly can neither guarantee product hygiene nor guarantee The fit of the product.

Yuhuan Shengjiu Mould Co.,Ltd is the leader in disposable medical mould industry. If necessary, please call us: https://www.medicalmould.net/product/Because the curled part of the oxygen mask mould is in direct contact with the pilot’s facial skin, it is required to be comfortable, free of allergic reactions and special odors. From the perspective of the oxygen masks currently in service and under development in the United Kingdom, the United States, France and other countries, they all use soft silicone rubber materials that are resistant to aging, oxidation and ozone, and have no abnormal odor (for example, Sauer A hardness of 30-40 degrees silicone rubber ), it has sufficient elasticity and certain rigidity to maintain the shape of the cover. Since the connecting part of the mask and the device needs to be guaranteed to have sufficient rigidity and strength, different strength, rigidity, and flexibility requirements are put forward for different parts of the oxygen mask to meet different usage requirements. Since the bottom of the oxygen mask needs to be in contact with the human face, the edges of the products produced cannot fit well with the user’s face, and the edges of the products produced due to moulds and other reasons are not flat enough to ensure the contact with people For comfort, a rubber strip that fits the face is usually buckled on the mask. However, the rubber strips are generally assembled manually, which not only has low production efficiency but also greatly wastes labor. This kind of manual assembly can neither guarantee product hygiene nor guarantee The fit of the product. Yuhuan Shengjiu Mould Co.,Ltd is the leader in disposable medical mould industry. If necessary, please call us: https://www.medicalmould.net/product/0 Reacties 0 Deel acties

Meer blogs